Pioneering Innovation in Port Operations:

How UMEX is increasing sustainability and productivity

Romanian operator UMEX relies on Nemetschek dTwin to digitize berths, storage areas and warehouses and link it with real-time data. So Umex can monitor the entire ship unloading process and increase sustainably energy efficiency and productivity.

Established in 1978, UMEX is a leading port operator. Located in Constanta North Port in Romania on the Black Sea coast, it initially specialized in industrial equipment and project cargo. UMEX’s leadership has adapted its operations to meet changing market demands, and today it operates five versatile berths. These handle bulk, grains, fertilizers, liquids and various steel products. The company’s extensive facilities include open storage areas, warehouses, and specialized infrastructure for different cargo types to support its clients’ needs with comprehensive infrastructure. This flexibility enables clients to use UMEX for all their cargo needs without seeking multiple terminals.

With its geographical position, the UMEX team is focused on innovative projects that challenge the status quo in port operations. “At this moment, UMEX can already provide everything our clients demand. But we want to do more than this; we want to innovate. Because while it's easy to reach the top of the mountain, it's very difficult to stay there. And what we are bringing into our projects now is something that you cannot find in any traditional port terminal,” explains Cristian Țăranu, the general manager of UMEX.

“What we are bringing into our projects now is something that you cannot find in any traditional port terminal.”

Measuring and managing a sea of shifting costs

UMEX faces significant challenges stemming from the volatile external circumstances surrounding Constanta Port, the northernmost EU port near the conflict areas of Ukraine and Russia. The substantial volume of goods moving through Constanta – particularly those related to Ukraine – places a constant strain on its operations. Additionally, finding and retaining specialized manpower has become increasingly difficult. To address these challenges, UMEX invests heavily in personnel training programs, sponsoring specialized trade training departments at local universities. But, despite all these efforts, the need to increase efficiency remains.

Another notable challenge is the number of complex and rapidly shifting activities happening simultaneously in UMEX’s facilities. To support their clients and the stability of their operations, the team must have a clear understanding of multiple data-driven metrics like operation volumes, productivity, warehouse usage, and loading efficiency, as well as labor, equipment, fuel, and power costs.

UMEX recognized some time ago that technology was key to facing these challenges. Therefore, it established several monitoring platforms, including the terminal's SCADA system, a 400 kW photovoltaic system, and a monitoring system for the facility's structural integrity. Some data was accessible on-site, while other information was available through various online platforms.

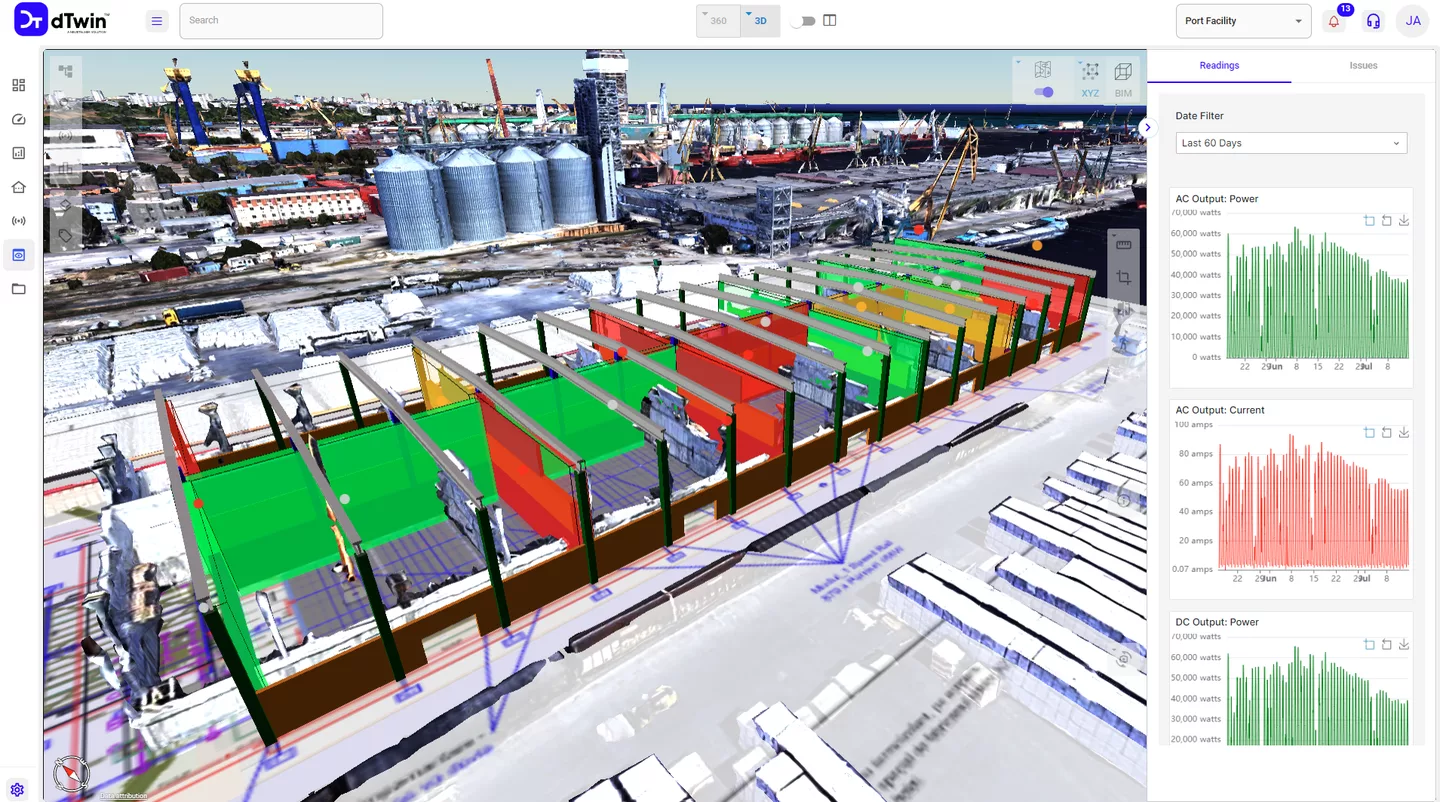

UMEX also created BIM models of its warehouses using Nemetschek ALLPLAN. And it was their local ALLPLAN partner ALLBIM.NET who introduced UMEX to a new solution by Nemetschek; dTwin – a platform for visual analytics and connected intelligence for built assets. The platform harmonizes all visualizations of a facility – like BIM models, 3D point clouds or panoramic pictures – in a digital twin, connecting data from all sources and IoT sensors to provide real-time insights and enable contextual and data-driven decisions. Already familiar with the power of BIM, it quickly became apparent that there was the opportunity to use dTwin to create a one-stop-platform for data from UMEX’s entire suite of solutions.

BIM models for operations

A seamless journey from BIM model to digital twin

Due to the facility's existing BIM model and IoT systems, creating the digital twin for UMEX was efficient and quick, and the initial model was up and running in about one week. Customizing and fine-tuning the platform took approximately two months. Daniel Nistorescu, Projects and Investment Manager explains more: “Creating the strategy, customizing the platform, and fine-tuning every aspect to our specific needs did require careful consideration and discussion with the dTwin team, and this took about two months. But their support was exceptional and the process was quite frictionless.”

Today, dTwin provides real-time data on the photovoltaic system's production and usage and continuously monitors the building's structure, signaling any malfunctions or deficiencies that could result in a loss. The app also acts as a comprehensive source of ‘truth’, connecting as it does data from various systems. It tracks the entire operational flow from vessel discharging to loading trucks, trains, and barges, providing the management team with a clear picture for improving energy efficiency and productivity.

Those insights are visualized in charts that are accessible via customized dashboards or directly from the BIM model. Not only can users switch from the model to the real-time data with one click, they can also visualize this data in the model using heatmaps. This means that abnormalities and deviations can be seen at-a-glance.

“By using dTwin we will achieve a better understanding of the cost that we are facing and we can propose better solutions for our clients with respect to the tariffs that we present, of the operations that we perform, and of the algorithm that we use in order to better discharge or load their cargoes,” sums up Daniel Sternberg, Commercial Manager of UMEX.

Real-time data from IoT sensors

Clear picture about the energy consumption and productivity, tracking of the entire operational flow from vessel discharging to loading, better solutions and tariffs for clients

"I think the sky's the limit in the future with dTwin, because we can easily add other sensors, we can also fairly easily scale to other terminals or locations that UMEX is handling..."

Real-time data fuels accurate cost determination

In the future, the platform can be expanded with additional sensors and systems, and scaled to other UMEX terminals, providing comprehensive data for management. Current plans include integrating new state-of-the-art port cranes and scaling dTwin to other terminals, providing real-time information to UMEX management and departments on the productivity of their depots and equipment.

Daniel Nistorescu gives an overview of what lies ahead: “I think the sky's the limit in the future with dTwin, because we can easily add other sensors, we can also fairly easily scale to other terminals or locations that UMEX is handling, and that would really put all relevant information at the disposal of management or other departments in UMEX.”